The world of industrial production is rapidly evolving, and laser marking machines are at the cutting edge. By utilizing precision laser technologies, manufacturers can achieve unprecedented levels of accuracy in their products.

With the power of these machines, businesses can unlock immense potential for efficiency and cost savings while creating high-quality results that exceed customer expectations. This article will explore how laser marking machines can elevate your operations to a new level and discuss the advantages they offer over traditional methods.

From increasing throughput rates to helping you stay ahead of industry trends, discover why harnessing the power of precision is essential for any business looking to push boundaries and stand out from competitors.

Realize Maximum Efficiency with Precision Marking Technology

Laser marking machines are revolutionizing the manufacturing industry as they enable businesses to achieve maximum efficiency in their production processes. With precision marking technology, laser machines can accurately mark surfaces with high-quality results and unprecedented speed.

This makes it possible for companies to make more accurate products faster than ever before. Furthermore, the superior accuracy of this technology allows manufacturers to reduce waste and cost while increasing productivity levels.

The advanced nature of laser markers also increases safety standards by eliminating manual handling or hazardous materials during operations. In addition, these highly precise machines allow for better customization options such as variable data printing and intricate markings on small parts that would be impossible with traditional methods.

Overall, investing in a laser marker is an excellent way for any business looking to improve its operational efficiency or deliver higher-quality products at lower costs. Precision marking technology offers numerous advantages over conventional techniques and provides unparalleled performance when it comes to achieving maximum efficiency in production processes.

Cutting-Edge Features of Laser Marking Machines

Source: instructables.com

Laser marking machines are making waves in the manufacturing industry for their cutting-edge features. With a laser beam precisely focused on a surface, intricate designs can be created with remarkably accurate detail and clarity.

These devices offer unparalleled precision compared to traditional manual methods of marking or labeling materials, allowing businesses to produce higher-quality products faster than ever before. One key feature that sets laser marking machines apart is their ability to create permanent markings on almost any substrate – including metal, plastic, glass, wood, and more.

This means that users can rest assured that their product labels will not fade away over time or become illegible due to wear and tear. Additionally, laser markers enable manufacturers to engrave logos or other images onto hard surfaces without having to worry about smudging or misalignments as would occur when using inkjet printers or rubber stamps.

Another advantage of these advanced machines is the speed at which they operate – some models can even mark up objects in less than one second! This makes them incredibly efficient tools for quickly producing large volumes of product labels without sacrificing quality control standards. Furthermore, since these devices require minimal maintenance once set up correctly there is no need for constant supervision while running jobs – freeing up staff resources for other tasks within the organization.

Finally, modern laser markers come equipped with sophisticated software programs designed specifically for improved user experience and productivity gains – such as customizable templates and automated image processing capabilities which streamline workflows by reducing operators’ input load significantly over manual processes alone. All this makes high-performance lasers an invaluable asset for any business looking to increase its bottom line through increased production capacity and cost savings down the line!

Harness the Power of Accurate and Detail-Oriented Results

Laser marking machines are capable of producing precise and highly detailed results, allowing companies to truly harness the power of accuracy. From engraving intricate designs on jewelry to etching unique serial numbers and barcodes onto products in manufacturing plants, these machines have revolutionized the way organizations create and manage their workflows.

With laser technology that can accurately replicate any design with exactness, businesses now have access to a powerful tool they can use for both creative expression and reliable production processes. The potential for detail-oriented results is limitless – from creating aesthetically pleasing artwork to ensuring successful product identification during shipping or storage operations.

Laser marking machines provide an invaluable resource that allows users to unlock the possibilities of precision.

Maximize Your Investment in Laser Markers

Source: mashvisor.com

Laser markers are capable of delivering precise results with unparalleled accuracy and speed. Investing in one can be incredibly beneficial for any business, but how do you ensure that you are getting the most out of your investment? A great way to maximize value is by understanding where the machines can be used for maximum efficiency. Evaluate which processes could benefit from laser marking technology and make sure those areas have appropriate access to these tools.

Additionally, exploring new ways to use this machinery can open up opportunities for cost savings or increased production speeds. Another key factor when maximizing investment in laser markers is maintenance and upkeep.

Regular inspections should be done on the components of the machine so they stay running smoothly and efficiently during operation, while also reducing downtime costs due to unexpected breakdowns or malfunctions. This will help maintain peak performance levels throughout its life cycle as well as reduce future repair expenses down the line.

Finally, investing in employee training programs ensures proper safety protocols are being followed while operating such powerful devices around hazardous materials or volatile substances like combustible gases or liquids near lasers. Having a skilled workforce ensures optimal usage of laser marker technologies leading towards higher-quality output with fewer mistakes resulting in more consistent products over time—maximizing ROI faster than ever before!

Conclusion

Laser Marking Machines have the potential to revolutionize manufacturing and production processes. With their precision accuracy and wide range of materials they can mark, laser marking machines are quickly becoming an invaluable tool for businesses looking to increase efficiency and reduce costs.

This technology offers unmatched speed, accuracy, and flexibility at a lower cost than existing methods making it an attractive option for many industries. The power of precision delivered by laser marking machines makes them a powerful weapon in the constant battle against time and money constraints that manufacturers face every day.

By unlocking its full potential, companies can leverage this disruptive innovation to drive operational excellence and gain a competitive advantage.

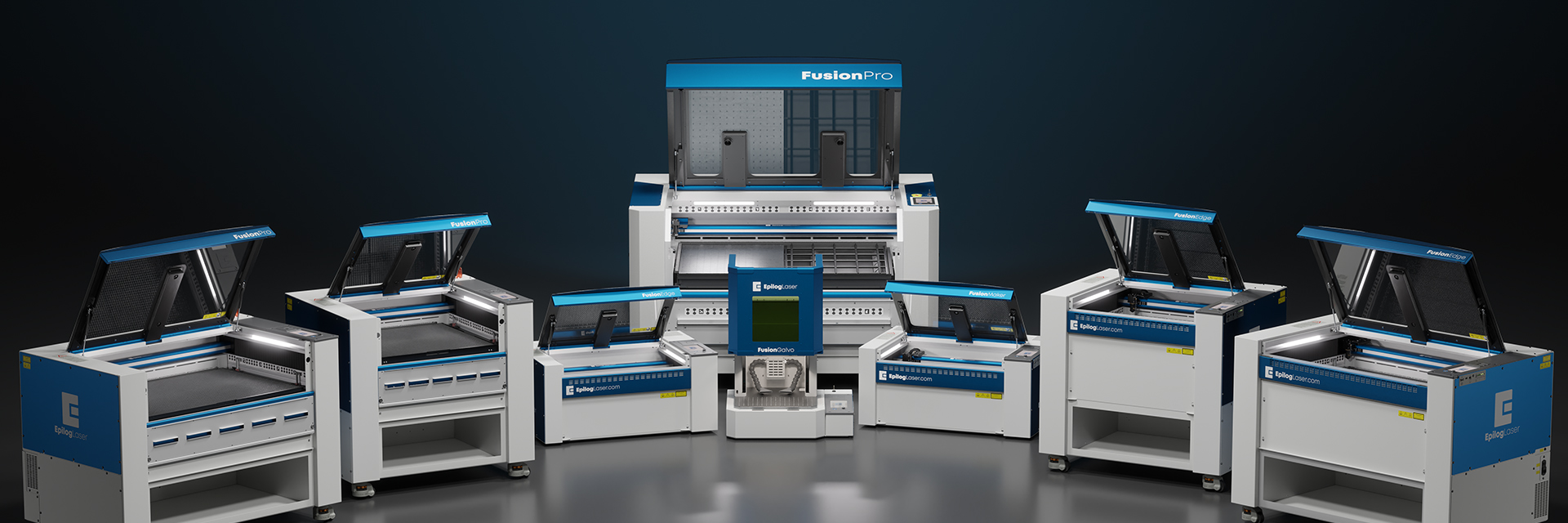

Source: epiloglaser.com