Are you curious about how PCB Assembly Online Technology works? Do you want to know what advantages it offers? Then this article is for you. In this comprehensive guide, we will explore the details of how online technology has revolutionized PCB assembly and discuss the various benefits that make it a great choice for businesses.

You’ll learn why companies are opting to use online technology as opposed to traditional methods and discover which features can help your business save time and money. By the end of this article, you’ll have a better understanding of PCB Assembly Online Technology and be able to decide if it’s right for your company. So let’s dive in!

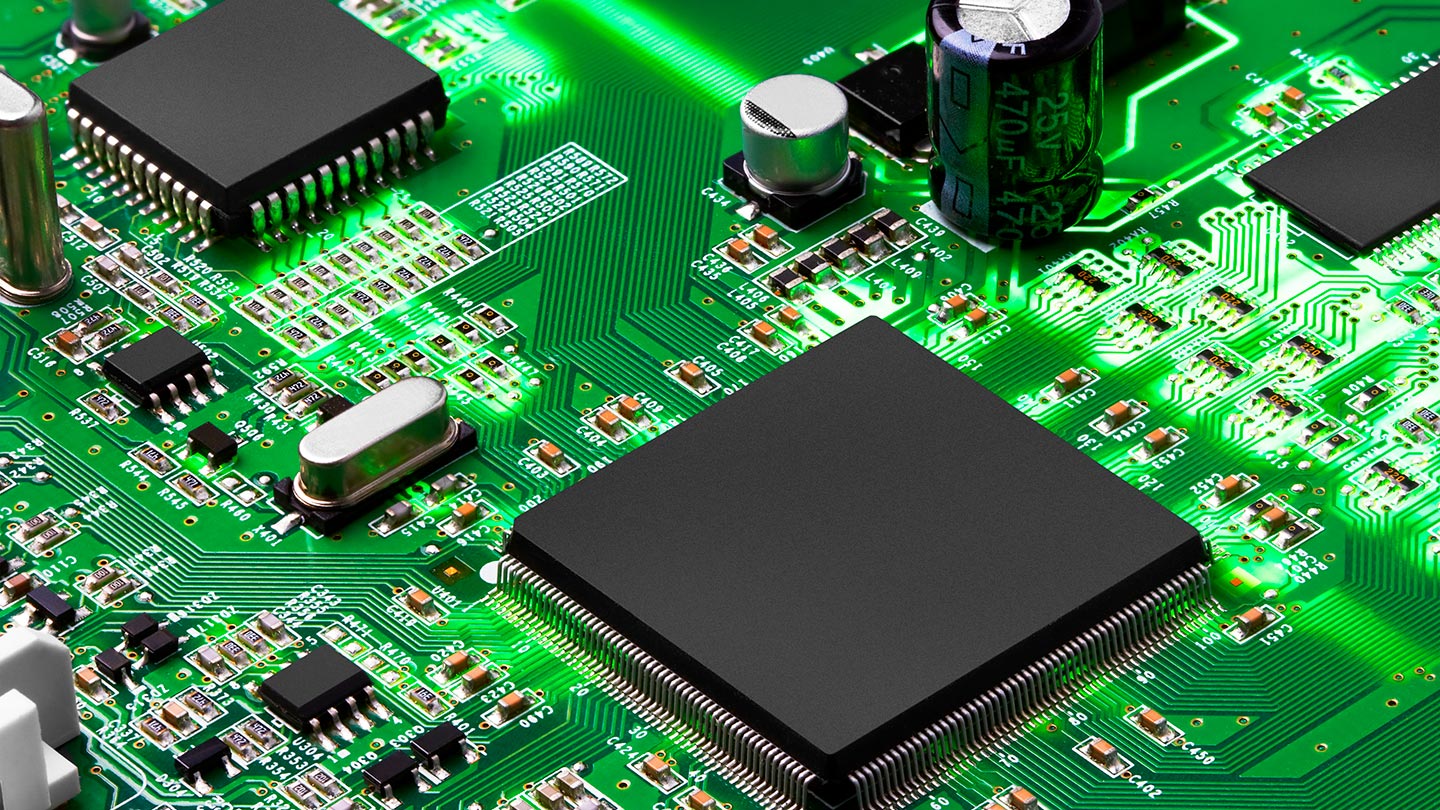

Understanding How PCB Assembly Online Technology Works

When it comes to understanding how PCB Assembly Online Technology works, it’s important to consider the various aspects of this technology. This comprehensive guide will explore how it all fits together and provide an in-depth look at its advantages. At the core of this technology is a combination of hardware and software that performs automated assembly operations on printed circuit boards (PCBs). The process begins with a set of instructions provided by the customer or designer, which are used to configure the machine for production.

Once configured, the machine can be operated remotely via a web interface or locally through dedicated controls. During operation, parts are placed onto designated locations on the board using robotic arms and vacuum nozzles based on pre-programmed coordinates determined by CAD software. Once components have been placed correctly, soldering occurs either through wave soldering machines or reflow ovens depending on component type and size requirements.

Through these processes, electronic assemblies can be manufactured quickly with precise accuracy when compared to manual assembly methods. Additionally, online systems offer cost savings due to their ability to run large batches efficiently without sacrificing quality control standards such as those used in traditional factories. Overall, PCB Assembly Online Technology provides numerous advantages over manual assembly methods including reduced labor costs as well as improved efficiency in terms of both time and accuracy during production cycles. By utilizing robotic automation combined with existing design systems like CAD programs customers can take advantage of high-volume orders while still maintaining quality control throughout each step in the manufacturing process — from component placement down to final inspection before delivery

Benefits of Utilizing PCB Assembly Online Technology

Source: airproducts.com

The utilization of PCB Assembly Online Technology offers several advantages for businesses looking to optimize their production processes. Firstly, it allows for more accurate and precise assembly operations, helping to reduce costs associated with materials waste and labor time.

In addition, these technologies can help businesses save money on inventory management as well as improve the quality assurance process by providing real-time data about the parts used in the assembly process. Furthermore, utilizing PCB Assembly Online Technology helps streamline communication between suppliers and manufacturers which results in faster delivery times and a better customer experience overall. Finally, this technology is highly scalable which means that businesses can easily increase or decrease the amount of boards they are producing without having to invest in additional resources or personnel training.

Different Types of Components Used in PCB Assembly Online Technology

When it comes to PCB Assembly Online Technology, there are a variety of components that make the process possible. These include circuit boards, resistors, transistors, and diodes which all work together to form complete systems. Additionally, many other types of components can be found in these assemblies such as capacitors for energy storage purposes or integrated circuits for more complex operations.

Furthermore, connectors and wires are used to join the different parts together while switches act as control points within a system. Different materials may also be used depending on the application with some being better suited than others at tolerating higher temperatures or humidity levels. Finally, specialized software is often required to help design and analyze data from each component before they are put together into an assembly unit.

Tips for Successfully Integrating PCB Assembly Online Technology into Your Business Model

Source: cfr.org

- Establishing Goals for Integration: When integrating PCB assembly online technology into your business model, it is important to establish clear goals and objectives for the integration process. Identifying what you are trying to achieve with this new technology will help guide your decision-making process as well as ensure that the benefits of using these technologies outweigh any potential risks.

- Evaluating Options: After establishing goals and objectives, evaluate available options in terms of their features, cost efficiency, and user experience to narrow down which type of PCB assembly online technology best fits your needs. Be sure to conduct thorough research before making a final selection so you can make an informed decision on how best to integrate it into your business model.

- Training & Education: Once you have identified the right PCB assembly online technology for your business model, proper training and education should be provided to all employees who will use or interact with the system or platform being implemented. This is essential to maximize its effectiveness while minimizing any potential confusion or errors during implementation processes or when interacting with customers who may be using the same services through different platforms than yours.

- Testing New Technology: Before full implementation of a new system, test out the interface by running simulations under controlled conditions in order to simulate real-world scenarios without risking disruption if something does not go according to plan when fully integrated into operations. Doing so allows you to identify any issues prior to full integration thereby reducing risks associated with launching a new product too quickly without sufficient testing beforehand.